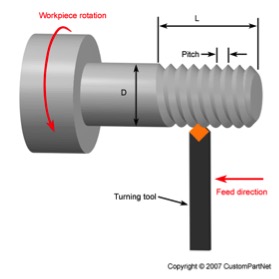

In this article, we will talk about the types of operations of turning. Turning is the most basic machining process, as described in the previous article - [CNC Turning] Fundamental introduction on CNC turning theory.

That is, the part is rotated while a single point cutting tool is moved parallel to the axis of rotation. Turning can be processed on the external surface of the part as well as internally, which is also called boring. The material used for this production is generally a work piece generated by other processes, such as casting, forging, extrusion or drawing.

Part 1

Few specific turning operations, such as tapered turning, spherical generation, hard turning, facing, parting and grooving, will be explained below.

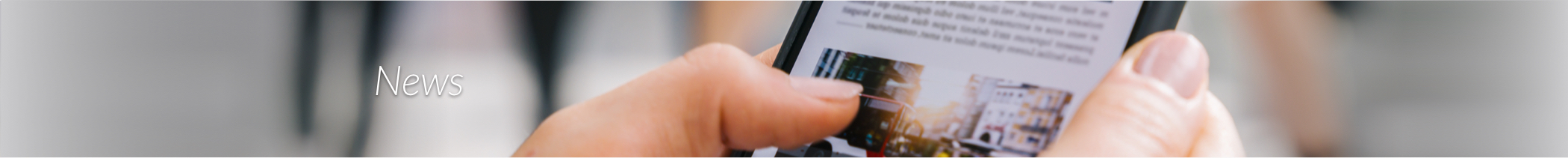

1. Tapered turning

Figure A. Tapered turning

Taper turning means, to produce a conical surface by gradual reduction or increase in diameter from a cylindrical work piece. This tapering operation has wide range of use in construction of machines. Almost all machine spindles have taper holes which receive taper shank of various tools and work holding devices.

2. Spherical turning

Spherical turning means to produce a ball shape on the work piece.

Figure B. Spherical turning

3. Hard turning

Hard turning means, to turn materials with a Rockwell C hardness greater than 45. It is typically performed after the work piece has been heat treated.

The process is intended to replace traditional grinding operations. Hard turning is appropriate for parts requiring roundness accuracy of 0.5-12 micrometers, and/or surface roughness of Rz 0.8–7.0 micrometers. It is used for gears, injection pump components, hydraulic components, among other applications.

Otherwise, when hard turning is applied for purely stock removal purposes, it competes favorably with rough grinding. When it is applied for finishing critical forms and dimensions, grinding is superior. Grinding produces higher dimensional accuracy of roundness and cylindricity. In addition, polished surface finishes of Rz=0.3-0.8z cannot be achieved with hard turning alone.

4. Facing

Facing in the context of turning work involves moving the cutting tool at right angles to the axis of rotation of the rotating workpiece. This can be performed by the operation of the cross-slide, if one is fitted, as distinct from the longitudinal feed (turning). It is frequently the first operation performed in the production of the workpiece, and often the last—hence the phrase "ending up".

Figure C. Facing

5. Parting

This process, also called parting off or cutoff, is used to create deep grooves which will remove a completed or part-complete component from its parent stock.

Figure D. Parting

6. Grooving

Grooving is like parting, except that grooves are cut to a specific depth instead of severing a completed/part-complete component from the stock. Grooving can be performed on internal and external surfaces, as well as on the face of the part (also known as face grooving or trepanning).

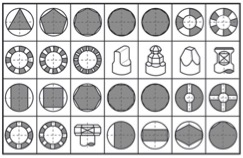

Figure E. External grooving Figure F. Face grooving

Part 2

Non-specific operations, such as boring, drilling, knurling, reaming, threading and polygonal turning, will be explained below.

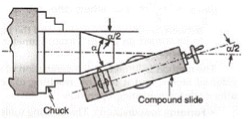

1. Boring

Boring is the process of enlarging a hole that has already been drilled (or casted), by means of a single-point cutting tool (or of a boring head containing several such tools), for example as in boring a gun barrel or an engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

Figure G. Boring

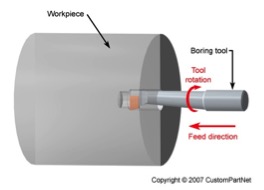

2. Drilling

Drilling is the process used to remove material from the inside of a work piece. This process utilizes standard drill bits held stationary in the tail stock or tool turret of the lathe. The process can be done by separately available drilling machines.

Figure H. Drilling

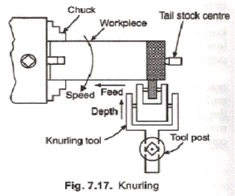

3. Knurling

The cutting of a serrated pattern onto the surface of a part to use as a hand grip using a special purpose knurling tool.

Figure I. Knurling

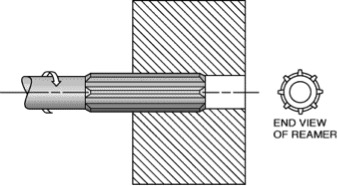

4. Reaming

Reaming is the sizing operation that removes a small amount of metal from a hole already drilled. It is done for making internal holes of very accurate diameters. For example, a 6mm hole is made by drilling with 5.98 mm drill bit and then reamed to accurate dimensions.

Figure J. Reaming

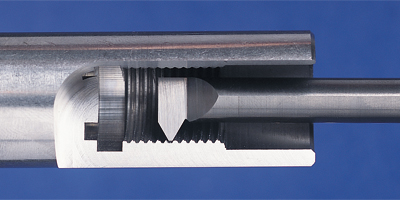

5. Threading

Both standard and non-standard screw threads can be turned on a lathe using an appropriate cutting tool. (Usually having a 60, or 55° nose angle) Either externally, or within a bore. Generally referred to as single-point threading.

tapping of threaded nuts and holes.

Figure K. Internal threading Figure L. External threading

6. Polygonal turning

Figure M. Polygon diagram

Figure M. Polygon diagram

In which non-circular forms are machined without interrupting the rotation of the raw material.

Figure N. Polygonal shape

Read more related topics: [CNC Turning] Fundamental introduction on CNC turning theory

Reference:

https://en.wikipedia.org/wiki/Turning - Article & Figure C,E,F

engineering.myindialist.com - Figure A.

www.micro-machine-shop.com - Figure B.

www.custompartnet.com - Figure G, H, L.

engineering.myindialist.com - Figure I.

dealertraining.cat.com - Figure J.

www.thinbit.com - Figure K.

www.cybercnc.com - Figure M.